Precision mechanical processing companies are currently not difficult to find on the market, however not all units provide reputable CNC machining services, ensuring technical requirements at reasonable prices. If customers are still confused between many choices, please trust and cooperate with Yamaguchi Vietnam Joint Stock Company because we possess the ability to process a variety of materials with high precision, ensuring quality. quality and always receive trust and appreciation from partners and customers.

1. Precision mechanical processing capacity: Yamaguchi Vietnam Joint Stock Company

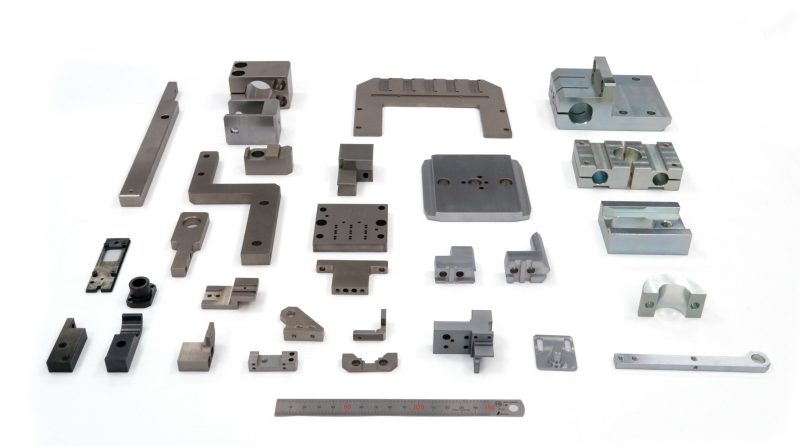

With more than 250 lathes and more than 60 milling machines, Yamaguchi Vietnam meets the processing capacity of 500,000+ products/month on 30+ types of materials with an accuracy of 0.003mm (data updated in early 2024):

Steel: S55C, S50C, S45C, SS400,…

Stainless steel: SUS316L, SUS316, SUS304, SUS303, SUS440C,… Processing on stainless steel materials is our strength.

Special steel: SKD11, SKD61, NAK80, P20,…

Aluminum: A2017, A7075, A6061, A5052,…

Red copper and yellow copper: C3604, C1100, Becu,…

Plastic: POM, MC, PMMA, Peek, Bakelite,…

Possessing a system of modern processing machinery and QC room equipment, Yamaguchi is committed to providing customers with processed products that fully meet technical requirements at reasonable prices, ensuring timely delivery. .

2. Processing process at Yamaguchi Vietnam

Yamaguchi Vietnam Joint Stock Company implements scientific processing processes, strictly follows ISO 9001:2015 standards and constantly improves and optimizes process performance. Below is an overview of our precision mechanical machining process:

Step 1: Receive and analyze customer requests

First, Yamaguchi will receive the customer’s request, then analyze in detail the technical criteria such as size, profile, tolerance, material,… and other requirements. In some cases, our engineering department can advise customers to improve drawing requirements.

Step 2: Design and program the machine

Based on customer requirements, Yamaguchi conducts detailed design and appropriate machine programming.

Step 3: Proceed with processing

After the process of setting up the machining system is complete, Yamaguchi conducts milling, turning, grinding, surface treatment, heat treatment, etc. to create accurate parts that fully meet the requirements. meet technical requirements.

Step 4: Check quality

Yamaguchi applies strict quality management processes according to ISO 9001:2015 standards throughout the manufacturing process and after completion, including sampling and 100% inspection methods.

Step 5: Packaging and shipping

After careful quality inspection, precision mechanical products will be packaged and shipped to customers as requested.

Normally, order completion time depends on a number of factors such as complexity of details, number of products, etc. However, Yamaguchi is willing to work 3 shifts/day, including Sundays and weekends. holidays to ensure delivery schedule.

3. Quality management capacity

Yamaguchi Vietnam Joint Stock Company applies a strict and strict quality management process according to ISO 9001:2015 standards.

3.1. Check input materials

Yamaguchi conducts inspection of incoming materials according to AQL sampling standards, including testing for uniformity, hardness, ductility, durability and other factors to ensure material quality meets technical requirements. , ensuring suppliers meet and comply with Yamaguchi’s quality management system.

3.2 In-process inspection

During the processing process, Yamaguchi continuously performs quality checks to ensure that technical specifications are fully met thanks to a system of modern testing equipment such as 3D CMM measuring machines and roughness meters. , hardness tester, microscope,… At the same time, ensure change control (ECR/ECN) according to 4M criteria.

Test the sample first.

Check in batches.

Customer approves production sample (PPAP).

Change control (ECR/ECN) according to 4M criteria.

100% inspection (according to customer’s request).

3.3. Check the finished product

After processing is completed, Yamaguchi performs final inspection to ensure finished product quality before shipment by sampling inspection method or 100% inspection according to customer requirements.

4. Some highlights of precision mechanical processing services at Yamaguchi

Besides processing quality and good processing capacity, Yamaguchi Vietnam is always trusted and prioritized by customers for many reasons:

Advanced system of machinery, equipment, and processing technology applied to the production process, ensuring quality and providing high performance.

Providing a variety of services, including milling, CNC turning, jig design and manufacturing, combining with reputable partners to perform surface treatment and heat treatment,…

Our staff is professionally qualified, experienced, and dedicated to their profession, ready to advise and provide optimal solutions for customer requirements.

Dedicated customer service, always ready to listen and advise and support customers in the fastest and most timely manner.

If customers are looking for a reputable precision mechanical processing company with many years of experience, Yamaguchi Vietnam is a worthy choice. With good processing quality and dedicated customer service, Yamaguchi is always trusted and highly appreciated by customers. Please contact Yamaguchi hotline, our experts will advise and support customers enthusiastically and thoughtfully.

YAMAGUCHI VIETNAM JOINT STOCK COMPANY

Office: 8th Floor, Sacombank Building, Le Duc Tho, My Dinh 2, Nam Tu Liem, Hanoi

Factory 1: Lot E3, Thanh Cong Street, Phung Town Industrial Park, Dan Phuong, Hanoi

Factory 2: Lot A4, Doc Lap Street, Phung Town Industrial Park, Dan Phuong, Hanoi

Factory 3: Lot A1, Doc Lap Street, Phung Town Industrial Park, Dan Phuong, Hanoi

Da Nang: No. H01/16k137 Le Van Hien, Ngu Hanh Son, Da Nang

Tel: (+84).24.6684.4282 – Email: info@yamaguchi.vn

日本語

日本語 Tiếng Việt

Tiếng Việt