• Yamaguchi operates a quality management system according to ISO 9001:2015.

• Perform IQC, IPQC, and OQC processes including defined sampling frequency and sampling plan.

• Work instructions for all operation and testing processes are available and put in process.

• 4M Change Analysis and Statistical techniques e.g. Pareto diagram, fishbone diagram, and control chart,… are applied to quality issue analysis and quality improvement.

• Implement PFMEA and PPAP. Key characteristics are identified in the control plan and are derived from FMEA.

• Apply process capability studies (Cp/ Cpk) and control chart to critical machining/ assembly/ testing process.

• A system to monitor the correct revision of drawings, change notices, and specifications is in use.

• A first in – first out (FIFO) system is utilized.

品質管理

検査設備

設備

数量

三次元測定機(CMM)

2

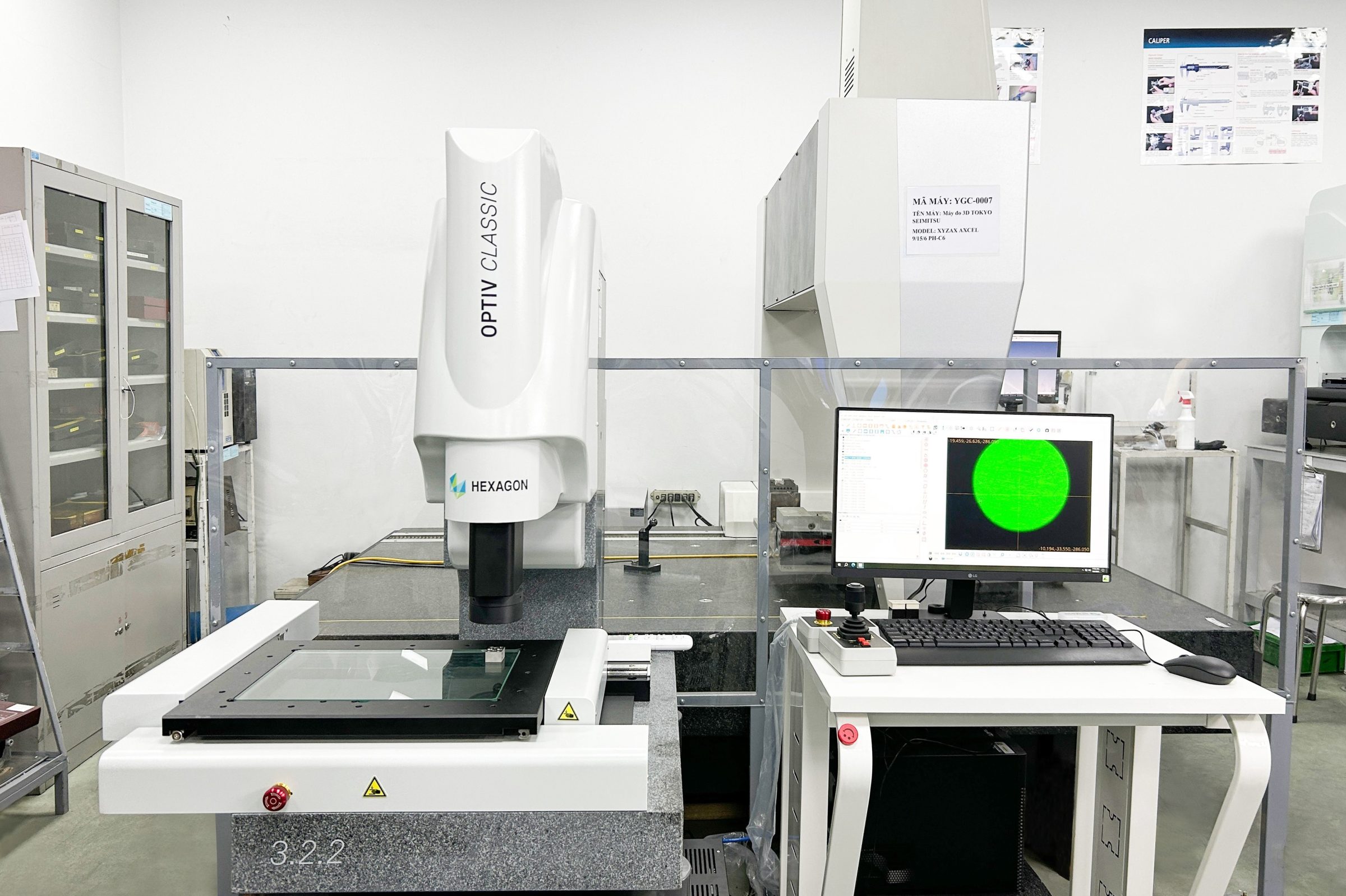

2次元測定機 (VMM)

2

2D IM画像寸法測定器

3

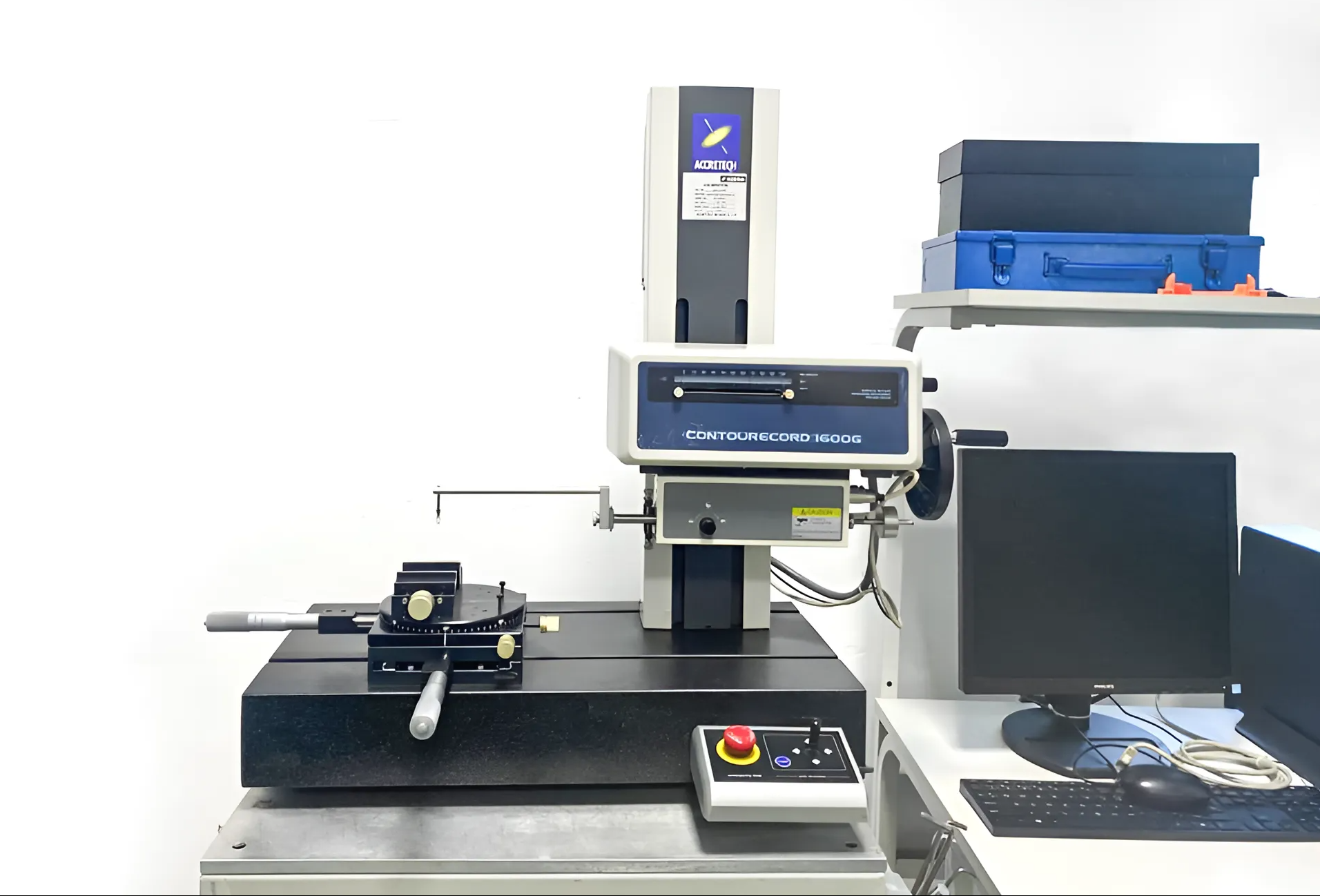

形状測定機

2

面粗さ測定機

3

円筒真円度測定機

1

硬度測定機

1

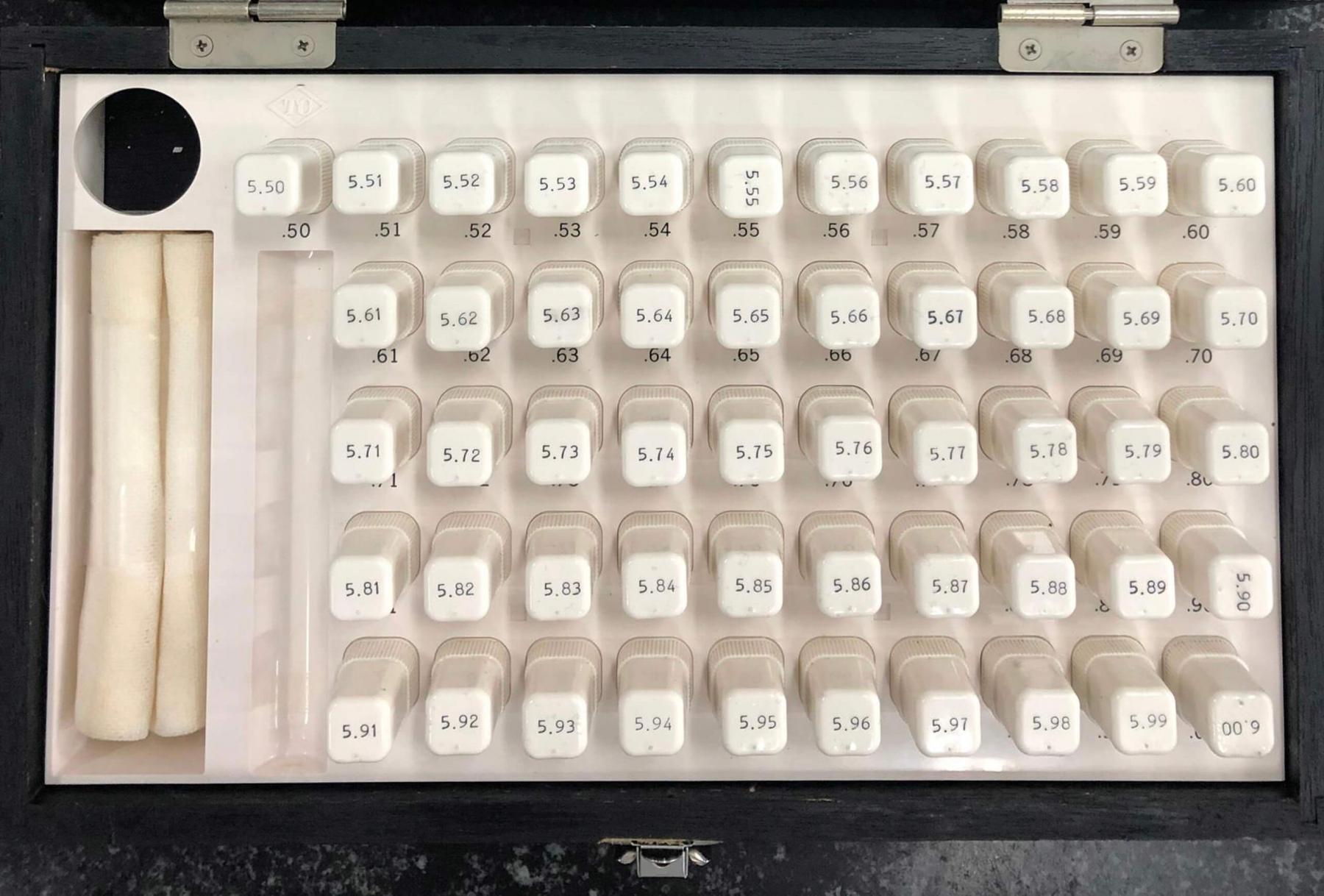

Profile測定機

2

部品検査用顕微鏡

40

THIẾT BỊ KIỂM TRA

設備

数量

三次元測定機(CMM)

2

2次元測定機 (VMM)

2

2D IM画像寸法測定器

3

形状測定機

2

面粗さ測定機

3

円筒真円度測定機

1

硬度測定機

1

Profile測定機

2

部品検査用顕微鏡

40

English

English Tiếng Việt

Tiếng Việt